Design & Manufacturing at Ewing Aerospace

Featured Technology: Brave f7 FC & 55A 4IN1 ESC

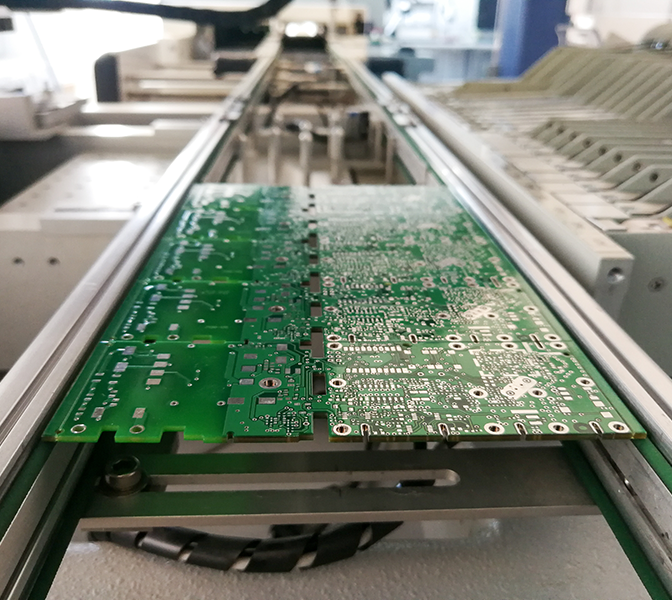

Electronics Manufacturing

- • Automated Assembly Lines: High-speed Surface-Mount Technology (SMT) for efficient PCB production.

- • Through-Hole Assembly: Selective and wave soldering for robust component integration.

- • Quality Assurance: Inline Automated Optical Inspection (AOI) and functional testing for flawless performance.

- • Specialized Services: Wire terminal and cable assembly, plus conformal coating for environmental protection.

Sheet metal Fabrication

- • CNC Plasma & Laser Cutting: Precise cutting of aluminum and other metals.

- • CNC Routing/Drilling: Accurate processing of aluminum sheets.

- • Bending & Forming: Press brake and bend brake capabilities for custom shapes.

- • Riveting: Expertise in solid, flush, and pull rivets for secure assembly.

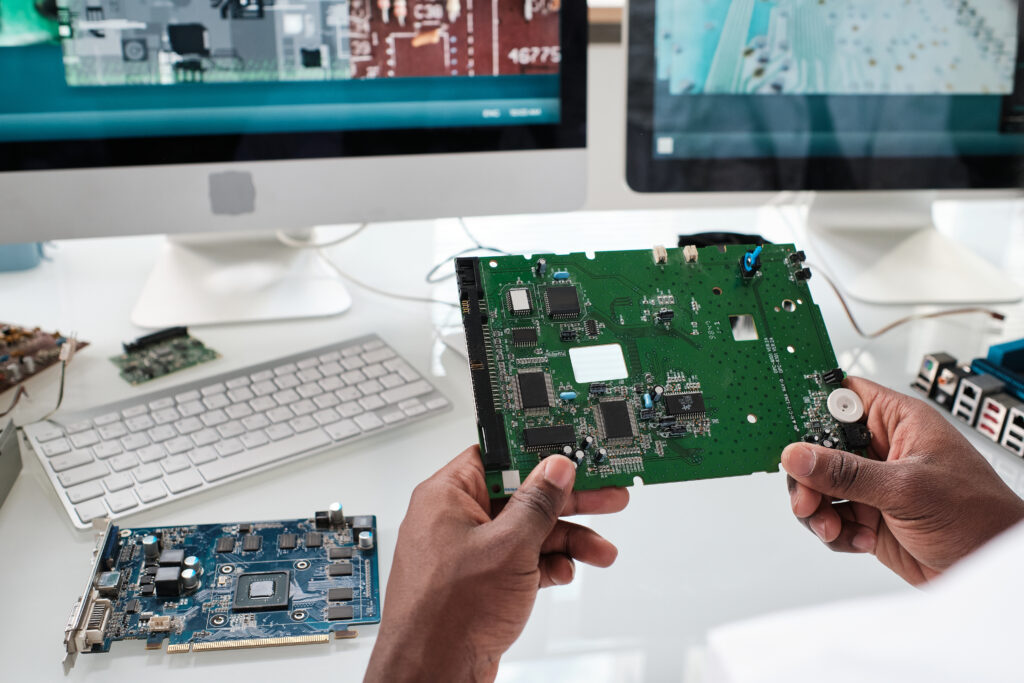

Engineering Services

- • Circuit Design: Schematic capture and PCB layout for optimized electronics.

- • Obsolescence Redesign: Modernizing legacy systems for continued performance.

- • Consulting Services: Expertise in composite materials, aircraft design, and brushless DC motor design.

precision Machining

- • 4-Axis CNC Milling: Precision milling for complex geometries.

- • Material Expertise: Machining of brass, aluminum, steel, stainless steel, titanium, and Delrin.

- • CNC Turning: High-accuracy turning for cylindrical components.

- • Composite Machining: Routing and milling of carbon fiber, fiberglass, and other composite sheets.

Laser cuting & Marking

- • Front Panel Fabrication: Laser-cut electronic panels for seamless integration.

- • Material Versatility: Cutting plastics and metals with high precision.

- • Laser Marking: Durable part identification and branding.

- • Soldering Stencils: Custom stencils for accurate electronics assembly.

Composite metal expertise

- • Mold Design & Fabrication: Custom molds for precise composite production.

- • Mold-Less Construction: Innovative techniques for rapid prototyping.

- • Material Processing: Milling, machining, and routing of carbon fiber, fiberglass, and Kevlar.

Manual assembly

- • PCB Enclosure Assembly: Seamless integration of electronics into protective enclosures.

- • Aircraft Sub-Assemblies: Kitting and assembly for streamlined production.

- • Sheet Metal & Composite Assembly: Precision construction for structural integrity.

- • Wiring Solutions: Reliable aircraft wiring for optimal performance.

CERTIFICATIONS

- • IPC-A-610: Certified for electronics assembly quality.

- • RoHS Compliance: Environmentally responsible manufacturing.

- • ITAR Compliant: Secure handling of sensitive military projects.

- • ANSI/ESD S20.20-2007: Electrostatic discharge protection standards.

- • ICAO/FAA Recognized: Certified for aviation manufacturing.

- • 14 CFR 89.520 DoC Holder: Compliant with FAA drone regulations.

- • NDAA Compliant: Adhering to National Defense Authorization Act standards.

- • Blue UAS Listed: Trusted supplier for U.S. military drone programs.

NEED HELP WITH YOUR PROJECT?